If you ever find yourself near Williamsport, PA, you have to stop by Bullfrog Brewery and try the Edgar IPA. It’s one of our favorites.

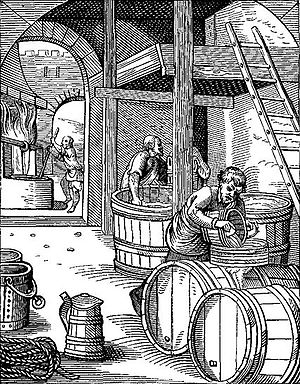

Beer Itself Might Have Led to Civilization

Brew Your Own: The How-To Homebrew Beer Magazine – Story Index – Brewing History – Archaeobeer:

The key ingredient that seems to anchor the switch from hunting and gathering to gardening, herding and farming, is the domestication of starchy staple foods. The first of these were grains — particularly wheat and barley — domesticated in the Near East and Asia Minor beginning around 12,000–10,000 years ago…

Domesticated starchy staples revolutionized life because they provided huge amounts of energy and, especially, because they could be stored to feed folks even through lean seasons. As I noted, wheat and barley were among the very first domesticated plant foods. And what do we do with wheat and barley? Well, we make beer, of course, and for that reason some archaeologists have argued that beer was the reason that people settled down and began to farm in the first place. In this view, beer itself might have led to civilization.

(18) Tuesday, June 1, 2010 Brew Day

It’s the last day of my vacation and I’m going to brew my Best Bitter. There’s an 80% chance of rain today. AccuWeather says the morning rain should be past by 8:00 a.m. and the afternoon rain shouldn’t start until after 1:00 p.m.

7:38 Collecting ingredients, removed yeast from fridge and smacked, finishing mash and sparge calculations. I’m going to try adding a half-teaspoon of gypsum to the mash.

8:03 It’s raining. Haven’t started to set up yet. Still gathering equipment and ingredients. Printed out recipe and placed in a sheet protector. Finishing my coffee.

9:02 Brewery set up (in the garage). Weighing grains.

Maris Otter is nicely tasty. Like a good breakfast cereal. Nice plump blonde kernels.

Malted wheat tastes about the same. Maybe slightly sweeter or saltier. Crunchier too.

Medium crystal is much crunchier. Sweeter with subtle toasty flavors. A hint of dried cherry.

Pale chocolate is mild with hints of sweetened coffee.

9:14 Grains weighed and crushed.

9:34 Heating mash water.

9:56 Mash water heated. Doughing in.

10:01 Mashing.

10:18 Ran into town to get a replacement propane tank for my empty spare. Got the last one. Remembered I hadn’t added the gypsum to the mash. Added and stirred. Temperature holding steady.

10:29 Collected sparge water.

10:37 Chewing on malted wheat. An oriole just flew by and there’s a pileated squawking nearby. Gretchen thinks they may have a young one this year. Still getting occasional showers.

10:47 Lighter gave out. Had to find matches. Heating sparge water.

10:58 Sanitizing carboy.

11:05 Vorlauf and lautering. First runnings taste like chocolate milk. 15.1 Brix (1.060 SG).

11:15 Forgot to close the drain valve on the kettle. Lost more than half a gallon before I realized what was happening. Just over three gallons of first wort remaining. Floor is wet and sticky. Sparging.

11:22 Second runnings 4.7 Brix (1.019 SG). Total is just shy of 7 gallons at 9.4 Brix (1.037 SG). Don’t know whether to do a 60 minute boil because of the reduced volume or stay with the 90 minutes for the sugar concentration.

11:40 Checked ingredient stash. No DME. Note for future: keep a few pounds of DME on hand. Poured myself a homebrew. Hosed down garage floor.

11:44 I just checked the recipe and the expected boil gravity is 1.033. Even with the loss mine is 1.037. Maybe I’ll go for a 60 minute boil after all. Perhaps my efficiency was higher than expected. Rechecked gravity. Around 10 Brix looks right.

11:52 Checking hops. They’re actually 9.2% AA. Expected 8.5% AA. Should actually use 0.92 oz.

11:59 Boiling… and there goes the alarm test at the VFD.

12:10 Okay. All is not lost. Sky is not falling. I learned a lesson today. There are two valves to remember to close. One on the mash tun, which I remembered. One on the boil kettle, which I did not. Experience is what you get when you don’t get what you want. Today I gained experience.

12:30 Bittering hops are in. 0.92 oz of bagged 9.2% AA Centennial pellet hops.

12:50 Lunch is black beans and rice and another homebrew.

1:10 Connected hoses to immersion chiller.

1:12 It’s raining again.

1:15 Immersion chiller in to sanitize. Added Whirlfloc™ tablet.

1:20 Flavor hops added. It’s raining again.

1:30 Aroma hops in. Flame off. Cooling water on. Stirring.

1:51 Chilled. Whirlpooled. Rinsed chiller.

2:00 Draining to carboy.

2:31 Drained. Aerated. In fermentation chamber. Cleaning up.

2:49 12.2 Brix OG (1.048 OG, target was 1.042). Pitched. Currently 69 °F. Set point is 68 °F. Attached heat belt to carboy. Inserted thermowell and temperature probe. Attached airlock.

Note for next time: Save some of the spent grain for bread!

Update: It’s Thursday morning (6/3) and it appears the fermentation is finished. The kreusen is starting to fall and the airlock is slowing down. I guess it makes sense it would be quick. It was a low gravity beer to start with, so there was not much sugar to convert to begin with. I’ll check the gravity later. If it’s done, I’ll add the dry hops.

Update: It’s Thursday evening (6/3) and just checked the gravity. It’s 9 Brix (1.027). The target is 1.012 FG, so it still has a ways to go. I swirled the carboy to rouse the yeast.

Update: It’s Friday evening (6/4) and just checked the gravity again. It’s 6.5 Brix (1.012) which was the target. 4.8% ABV. 158.2 calories per 12 oz. serving. Now to add the dry hops.

Update: It’s Saturday morning (6/5) and I’ve been doing some thinking about this brew. The OG is freaking me out. Recall that I lost about three quarts of the first runnings — the best stuff with the most sugar — onto the floor of my garage. If I had not, and had ended up with an OG of 1.048 instead of my 1.042 target, that would have meant that I would have gotten 80% efficiency. Since I did lose that wort, it means my efficiency would have had to have been even better than 80%. I batch sparge and the last two batches I did were just about 70% efficient. Except for remembering to close the valves I followed the same procedures, so I have no reason to believe this batch should be much more efficient. The only conclusion I can come to is that I measured the weight of the grains wrong. Since the Maris Otter is the biggest contributor, I have to assume I used too much of that.

Update: It’s the following Saturday morning (6/12) and I’m going to bottle today. First I’m going to make up the priming solution so it has a chance to cool by the time I’m otherwise ready. In theory, this is a Best Bitter and Charlie Papazian says¹ that the carbonation level should be between 0.75 and 1.3 volumes of CO₂. I’m going to shoot for the middle and say one volume is my target. It has been fermenting at 68 °F, so I should be starting with around 0.86 volumes already, which means I’m going to need to generate another 0.14 volumes with my priming solution. I’m going to eyeball the volume and say I’ll get 5 gallons and I’m using corn sugar, so I’ll need about 0.37 oz (10.5 g) to get that much.² As a sanity check, that is less than a tablespoon.

I’m going to be using flip-top pint bottles, and if I’ve really got 5 gallons, I’ll need 40 of them.

I checked the gravity again and it came out to 6.2 Brix (1.010 FG). 5.0% ABV. 198.4 calories per pint.

I ended up with 35.5 pints. Given the sugar I added, the actual carbonation will be 1.02 volumes of CO₂, which is close enough to make no difference.

The initial reaction is “nice hoppy aroma, tastes like hop juice.” Maybe the flavor addition is too much or even unnecessary. We’ll evaluate again when the carbonation is done and the serving temperature is appropriate.

¹ Charlie Papazian, The Home Brewer’s Companion <http://www.beertools.com/forum/viewtopic.php?p=11625&sid=bc62db82f5350363b0e70498a78a314b#11625> [accessed Sunday, May 2, 2010]

² Michael L. Hall, Ph.D., ‘Brew by the Numbers – Add Up What’s in Your Beer’, Zymurgy (Summer 1995) <http://www.homebrewersassociation.org/attachments/0000/2497/Math_in_Mash_SummerZym95.pdf> [accessed Sunday, February 7, 2010]

Brush Valley Brewing’s Best Bitter (BVB³)

This is my own recipe.

I formulated this recipe to produce five gallons (19 L) of beer for packaging. I assume a loss due to trub of a half-gallon in the fermenter and another half-gallon in the boil kettle. That will leave six gallons (22.7 L) at the end of the boil. I assume a boil-off rate of about one gallon per hour, which means I need 7.5 gallons (28.4 L) at the start of a 90-minute full-volume boil. I use bagged pellet hops for all hop additions.

Recipe: Brush Valley Brewing’s Best Bitter (BVB³)

Brewhouse Efficiency: 70%

Pre-Boil Volume: 7.5 gallons (28.4 L)

BG: 1.033 (8.29 °P)

OG: 1.042 (10.47 °P)

FG: 1.012 (3.07 °P)

ADF: 70%

IBU (Rager): 40

ABV: 3.9%

Color (Morey): 12.6 SRM (32.1 EBC) – Light Copper

Boil: 90 minutes

| Grains | Weight | Percent |

|---|---|---|

| Crisp Maris Otter (4 °L) | 8 lb. (3.63 kg) | 82.1 |

| Simpson’s Medium Crystal (55 °L) | 1 lb. (454 g) | 10.3 |

| Rahr White Wheat Malt (2.8 °L) | 0.5 lb. (227 g) | 5.1 |

| Thomas Fawcett & Sons Pale Chocolate Malt (207 °L) | 0.25 lb. (113 g) | 2.6 |

| Hops | IBU | |

| Centennial 8.5% AA, 60 min. | 1.0 oz (28 g) | 32.7 |

| Centennial 8.5% AA, 10 min. | 1.0 oz (28 g) | 7.1 |

| Centennial 8.5% AA, 0 min. | 1.0 oz (28 g) | 0 |

| Centennial 8.5% AA, dry hopped | 1.0 oz (28 g) | 0 |

| Yeast | ||

| Wyeast 1999 Whitbread Ale |

Step by Step

This is a single step infusion mash at 2 qt./lb. with a batch sparge. Mix the crushed grain with 5 gallons (19 L) of 165 °F (74 °C) water to stabilize at 156 °F (69 °C) for 60 minutes. Vorlauf and lauter to collect 3.75 gallons (14.2 L) of wort.

Sparge with 3.75 gallons (14.2 L) of 170 °F (77 °C) water to bring the collected volume to approximately 7.5 gallons (28.4 L). Boil for 90 minutes. While boiling, add the hops according to the hopping schedule. Cool the wort to 68 °F (20 °C). Transfer to a sanitized 6.5 gallon (24.6 L) glass carboy fermenter.

Pitch yeast and aerate the wort. Hold at 66 °F (19 °C) until fermentation is complete. Add dry hops. Let the beer condition for one week and then bottle. Carbonate to 1.0 volumes using 0.5 ounces (14 g) corn sugar. Bottle condition for two weeks.

Cider Notes

When I first decided to make cider, I turned to the home brew forums for answers to my questions. Here is what I found, in the form of an imaginary online conversation.

Gretchen and I have been growing our own apples for years now. We bought a cider press a few years back and have been making ourselves sweet cider every fall. As I get back into home brewing, after a fourteen year hiatus, I thought I would try a hard cider. How many apples will I need to pick to get enough for a batch and which should I use?

On Fri Jul 07, 2006 7:25 am, hiddendragonet wrote:

Grocery store juice/cider is vastly inferior to fresh-pressed, non-preservative cider from an orchard, so definitely go that route if you can.

In Nov, 2004, Paul Zocco wrote:

Get your hands on the freshest cider possible, and taste it. If it tastes good, use it in your brew.

On Wed Mar 02, 2005 5:55 pm, Bardon wrote:

If you start with good apples, you get good cider. The juice you buy in the grocery store is made for fresh drinking, not fermenting. If you can’t grow your own or find a local orchard with cider apples, try to stick with a good fresh local juice in season. Another option is to find someone with a cider press and gather unwanted fruit from your neighbors. There’s never a shortage of that! Just getting a juice made from lots of different apples will help your cider taste more like apples.

On Oct 12 2007, at 12:10 AM, bierboy wrote:

One bushel of apples yields 2–3 gallons of cider. You will need several different varieties of apples to make a cider.

On Tue Feb 28, 2006 10:20 pm, Ciderman wrote:

Many orchards will take their apples right from the cooler to the press. I like to let mine sweat a few days in the crates out of the cooler prior to pressing them to maximize starch to sugar conversion.

As a homebrewer, I know that the specific gravity — the measure of the amount of (possibly) fermentable sugar, and hence the potential alcohol — is an important parameter of the recipe. What specific gravity should I expect for apple juice? If it is not high enough, can I add sugar or honey to raise the gravity?

In Nov, 2004, Paul Zocco wrote:

Use your hydrometer to determine the specific gravity of your juice and its potential level of alcohol. (Assume that final specific gravity will drop to 1.000.) Adding fermentable sugars, such as honey, molasses, maple sugar, piloncillo or brown sugar will produce more complex flavors and a higher alcohol level.

For traditional cider, shoot for maybe 4% ABV (the BJCP guidelines say 4.5–7.0).

On Apr 26 2008, at 11:15 AM, OldTimeyDave wrote:

My local apple press makes juice upwards around 1.060 at times so it is extremely tough without an original reading. If you’d like to be even more sure the suggestion of taking a reading of the unfermented juice (if possible) is a solid idea, too.

On Jul 30 2007, at 11:20 AM, ewanzel wrote:

Most fresh ciders I have used in the past have around an SG of 1.040-ish. If you want a cider that’s low in alcohol you can always just pitch an english ale/cider yeast (I use S-04) and it will produce good results if given enough time to age/even out. Or as you suggested you can add sugar and/or honey to it, but in my opinion this tends to produce an overly dry cider with a hot flavor due to the alcohol… it takes a long time to age/mellow out. In my opinion the problem with Champagne yeast is that will survive conditions up to around 18% ABV (which means that your cider will ferment to dryness)… in my experience once you ferment to dryness it can be difficult to get a true apple flavor back. If you go with cote de blanc and a bunch of sugar you will be producing more of an country apple wine then a cider (which may not be a bad thing).

On Thu Nov 30, 2006, at 1:01 pm, Denny wrote:

After making many batches of cider, I’ve come to the conclusion that I prefer just juice, with nothing to raise the gravity. It may make it stronger, but in my opinion it doesn’t make it better.

Is it alright to use windfalls?

On Mar 6 2008, at 05:13 PM, Matt the Mead Maker wrote:

The English form of hard cider known as “scrumpy” was originally made with windfalls. In fact, I read somewhere that the term “scrumpy” meant “windfall apples” before it referred to the hard cider drink.

On Mar 8 2008, at 01:18 AM, BeesNBrews wrote:

Windfalls, mostly in good condition, would have been used. Our tendency toward 0% risk has forced commercial producers away from windfalls and all the way into [with hesitation] pasteurization. Face it, you have no control over what might relieve itself on a fallen apple. Come to think of it, you have no control over what winged creature might also relieve itself on an apple

The risk is yours to take. I use windfalls, but also campden. Twenty years ago we wouldn’t even have asked this question. Next thing you know, someone is going to tell us how much alcohol we can make at home; but alas, I digress…

In beer brewing, you boil the wort for a variety of reasons, but one of them is sterilization. Is it necessary to boil the apple juice when making cider?

On Oct 13 2007, at 11:41 AM, wayneb wrote:

In general, heating any juice will do two things — it will drive off volatile aromatics that add “nose” and depth to the flavor profile, and it will cause proteins in the liquid to link into longer chains. That protein thing is what causes heated pectin to “set,” which is a good thing if you’re making jelly, but a bad thing if you want clear cider. The pectin problem can be solved to a great extent by adding pectic enzymes, which will break the pectins back down into smaller compounds that don’t then contribute to haze in the final product. But once the aromatics from a juice are lost through forced evaporation at higher temperatures, there’s no recovering them.

On May 22 2008, at 04:34 PM, Matt the Mead Maker wrote:

If the pasteurization was done with heat, it definitely would have set the pectins. If you live near a homebrew store, just swing by and pick up some pectinase. You’ll only be out a couple of bucks and it’ll clear up any pectin issues in 24 to 72 hours.

On Nov 2 2007, at 04:31 PM, wayneb wrote:

Another tip — if you’re concerned about the viability of natural yeast in your UV pasteurized cider, take a couple of locally grown apples, peel them, and then drop the skins into your cider. Leave them there until the bubbling starts, and then strain ‘em out. That’ll inoculate all the local wild yeast that you need.

BeesNBrews mentioned Campden. What, exactly, is Campden anyway?

In Nov, 2004, Paul Zocco wrote:

As an alternative to heating, some cider makers prefer to add 50–100 parts per million (ppm) of sodium or potassium metabisulfite to their freshly squeezed cider before pitching their yeast. This is approximately one Campden tablet per gallon (3.8 L) of must. After you add the sulfite (which will kill any wild yeast and bacteria), allow the must to sit for 24 hours before the yeast is pitched.

On Wed Mar 29, 2006 12:56 pm, hiddendragonet wrote:

If you use campden or KMETA prior to pitching yeast, that vigorous stir the next day is really critical I’ve found. You really need to disburse the gas, or it will have a hard time getting off the ground.

What kind of yeast should I use?

On Tue Dec 05, 2006 1:29 pm, Sapo wrote:

Most here who strongly favor one yeast seem to go with English Cider, Sweet Mead, or wild. English Cider and Sweet mead supposedly do the best job of preserving the apple flavor, and not either skunking it with their own contributions or fermenting it out completely.

On Thu Mar 16, 2006 11:39 am, Denny wrote:

The main differences I note in cider with different yeasts is the dryness and apple character. I’ve found that using wine, champagne, or ale yeasts (especially if you add sugar to the cider) makes a VERY dry, tart cider with little apple character to it. Using natural yeasts, sweet mead, or cider yeast, the cider turns out a little less dry and still has a hint of “apple-ness” to it. Usually these days, I use nothing but fresh pressed apple juice with no sugar or anything else. I either let it ferment naturally or use the WY4766 cider yeast.

On Mon May 08, 2006 2:19 pm, Denny wrote:

I actually prefer “wild fermentation” over any cultured yeast I’ve tried, but there’s one VERY big caveat… I’ve never lost a batch to cultured yeast! For me, I’d say natural fermentation has been at best about 70% effective. The only times I’ve tried it have been when I had enough juice on hand so that I wouldn’t feel too bad if I lost a batch.

On Sep 14 2005, at 03:47 PM, HighTest wrote:

If you are using commercial yeast, make a starter using one quart of cider to one package of yeast.

In October 2007, Nathan Poell wrote:

The day before you brew your cider, make a starter. This step is optional, but it ensures that your yeast is proofed (i.e., alive) and will start fermenting your cider right away.

In Nov, 2004, Paul Zocco wrote:

You must, however, aerate the entire mix before primary fermentation.

Do I need to add anything else?

On Jul 14th, 2008, at 11:44 am, Jer Goode wrote:

Ascorbic acid is ok; it’s just vitamin C and is added to preserve color. Winemakers often add it at bottling. It won’t hurt anything. I also add a teaspoon of acid blend, a half of tannin, and some pectic enzyme.

In Nov, 2004, Paul Zocco wrote:

Some cider makers prefer to add pectic enzyme — usually at a rate of one quarter teaspoon per 5 gallons (19 L) — to improve the clarity of the end product. Adding yeast nutrients can also be a good idea, especially if you have added a lot of refined sugar to your cider must.

On Mon Sep 22, 2008 9:34 am Denny wrote:

I always use nutrient after having a not so good experience the one time I forgot!

On Sat Oct 04, 2008, at 10:01 am, Denny wrote:

All of my apples are very sweet… great for eating, but they make a kinda “insipid” cider. I find that if I add acid blend and tannin to simulate real cider apple varieties, it makes a much better cider.

Is there anything special about fermenting a cider?

On Sep 16 2007, at 03:55 PM, BikeBrewer wrote:

Fermenting in plastic can be OK, but I prefer to use… glass… You will get oxidation with plastic, so you can’t age at all.

I have heard that some people encounter a “rotten egg” smell during fermentation. Why is that?

On Oct 26 2007, at 10:36 PM, wayneb wrote:

The hydrogen sulfide smell (rotten eggs) comes usually from yeast that are fermenting under stress. The most common cause of that stress is lack of available nutrients, especially available nitrogen. If you detect the sulfide smell early in the fermentation, a dose of Diammonium Phosphate (DAP) yeast nutrient usually does the trick. Later on in the fermentation (after about the 50% attenuation point), the yeast don’t benefit from DAP additions. You can get rid of most of the sulfide smell just from stirring the batch. That will both get the sulfide out of solution, and also eliminate excess CO₂, which can also stress the yeast. If you leave too much sulfide in the cider, it will eventually bond with the alcohol in the brew to make mercaptans, which kind of smell like rotten cabbage, and are much harder to get rid of than the sulfides.

Do I want to rack the cider into a separate vessel for secondary fermentation?

On May 22 2008, at 08:36 AM, ScottS wrote:

My preference is to not put it in bottles until it tastes right. Eliminates the guesswork. Primary until fermentation is finished, secondary until it’s ready to drink, with a racking or two in there if it throws lots of lees.

What are lees?

On Dec 16 2007, at 09:53 PM, mike911 wrote:

Lees, in a nutshell, are whatever settles out of your wine, mead, cider, etc. Quite often it is the “spent” yeast cells that fall out of the must, but could also be fruit or spice particles, or pretty well anything else.

On Jun 14 2007, at 09:03 PM, Nurse Nan wrote:

As cider (or mead or wine or beer) ferments, the yeast multiply (breed) eat the sugar, produce CO₂ and alcohol and die. Dead yeast, impurities in your must and other unfermentable cellular debris (plant cellulose) fall out of solution as the specific gravity drops. If this happens too quickly/early in fermentation, it can sometimes take live/healthy yeast with it. This build up at the bottom of the fermentor are the lees/sediment. If left in place too long, they start breaking down, producing off flavors in your brew. That is why I rack.

In Nov, 2004, Paul Zocco wrote:

As in established brewing and winemaking practice, you must transfer (rack) your cider off its dead yeast and sediment. Do this after seven to ten days of fermentation. Leave the still fermenting cider in this secondary fermentation vessel for at least two more weeks.

On Jun 15 2007, at 09:47 AM, mike911 wrote:

In some cases people will leave their wine, mead, etc. on the lees for extended aging, called sur lie aging, which can add different flavors to it like a nutty flavor, but this is something which must be monitored or the nutty can turn into something else, which may not be desirable. I’ve never tried it myself, but there are others here who have, I believe. But yes, the reason is to clarify your final product.

Okay. There is an argument for going long in either primary or secondary. I can appreciate that. Styles and personal tastes and all. How about some typical times, though?

On Wed Aug 02, 2006 7:06 am, sirbrewzalot wrote:

It seems to me its better to wait at least 3 weeks. Ciders ferment slowly, and if you rack it after a week you’ll just have to rack it again because it will continue to ferment and throw lees.

On Wed Wed Sep 13, 2006 9:52 am, Denny wrote:

Be patient and don’t rush it.

On Wed Nov 02, 2005 11:12 am, Denny wrote:

I’ve found that I just need to forget about time completely when I make cider. A month or 2 in primary and 3-6 months in secondary is my usual schedule. Then I give them 1-2 years in the bottle. Cider seems to me to be much more like wine or mead than beer in that respect. But the real answer to how much time to give it is “Until it tastes good to YOU!”. Like most things in brewing, though, patience pays off.

On Wed Nov 10, 2004 12:45 pm, Denny wrote:

Time is on your side… when in doubt, do nothing!

On Oct 23 2007, at 09:01 PM, Stuster wrote:

I’d suggest not being in too much of a hurry with cider. I’ve found that the flavour tends to mellow and meld together from a reasonably long secondary (almost the only time I do secondaries). With my current batch of cider, I did 2 weeks in primary, then 4 months in secondary. It’s crystal clear now, and tasting pretty good.

On Oct 26 2007, at 12:57 PM, OldTimeyDave wrote:

My technique has a lot to do with playing by ear… or well sight, smell and taste in [this case]. I’ll usually let my primary go 2–3 weeks and sometimes a month. It depends on activity, OG, temperature, taste, yeast, etc.

It can sit in secondary for another month or so… Until I am happy with where it is headed and as long as the airlock still active.

On Sep 14 2005, at 03:47 PM, HighTest wrote:

Once primary fermentation is nearly completion (SG 1.010 or less), rack the cider to a sanitized glass carboy. Over the next few months expect the cider to throw lots of lees. Rack every two or three months until lee production stops.

On Mon Dec 03, 2007 at 9:21 am, wayneb wrote:

Now on to the length of time you need to be in the primary — a month is more than I leave any of my ciders, fruit wines, or meads in primary. My interpretation of “end of primary” is when I’m closing in on the final SG that I’d like the brew to have. Then I’ll rack off of the gross lees, which will usually slow fermentation dramatically, and I’ll keep the must in a carboy for several months while fermentation totally finishes up, then the wine clears. In years past, before the desirability of feeding yeast with nitrogen-based nutrients and vitamins was known, primary fermentations of several months were common — especially in meads, since the must from honey is nutrient poor. However, with application of nutrients to your must at the right times and in the right quantities, you can complete primary fermentation of virtually any recipe within a week or two.

What about bottle conditioning?

On Fri Aug 08, 2008 10:19 am, Denny wrote:

I use 1 oz. of corn sugar per gal. of cider for carbonation.

On Sep 14 2005, at 03:47 PM, HighTest wrote:

It is highly recommended to bulk age your cider for approximately 9 months. That is when it will approach it’s peak flavor, and when lee production is more or less finished. You can bottle earlier if desired, but you will likely get significant amounts of nasty tasting lees in the bottles.

On Oct 26 2007, at 12:57 PM, OldTimeyDave wrote:

As a rule I usually carbonate naturally by batch or bottle priming. I don’t think the cider is worth drinking for at least a month or two, 3 months is awesome and some folks say a year is best.

Cider is more of a slow food than beer is and can’t be made as rapidly.

On Jun 19 2008, at 03:51 PM, jwhite751 wrote:

Let them age, you will be amazed at how much better they will be after 3 months minimum. After 6 months you will be very impressed and even your friends will drink them. I have been brewing beer for 15 years and very seldom do they last past 6 months. Cider is just starting to be very good at that point and will continue to improve at a year or more.

On June 23, 2008, at 5:58 pm, krausenator wrote:

Most ciders need a minimum 4–6 months in the bottle to condition before they are good. So you may just need to wait.

I hear a lot of people say their cider is dry or still. Why is that?

On Jul 2 2007, at 12:44 PM, mikesarney wrote:

When you make cider without kegging, you can either have sweet and still, or dry and sparkling.

Adding sorbate inhibits the yeast, and allows you to have sweet cider. The problem is, without the yeasties doing their thing, you get no CO₂ for carbonation.

On Apr 25 2008, at 08:28 AM, ScottS wrote:

Attenuation rates are not applicable to things that have fully fermentable sugars. Cider and mead musts are fully fermentable, so the only barrier to fermenting everything is the alcohol tolerance of the yeast. Unless you add a TON of sugar to your cider, just about any yeast you use is going to ferment it to dryness.

On Apr 9 2007, at 12:12 PM, Matt the Mead Maker wrote:

If you add sorbates and want a sparkling cider, you’ll have to force-carbonate with kegging equipment. You’re not going to get a sweet, naturally carbonated cider due to the fact that fructose (the dominant sugar in apple juice) is 100% fermentable. Malt is not 100% fermentable and that’s why you can have residual sweetness in a beer and still be able to bottle-carbonate with sugar.

If you don’t want to buy kegging equipment and still want a sparkling cider with sweetness, you’ll have to add spices such as vanilla and/or cinnamon which create the perception of sweetness without imparting any actual sugars.

On Apr 9 2007, at 03:07 PM, wayneb wrote:

The other thing you could do is to add a more complex sugar (such as lactose), which will not ferment and will contribute a sweet taste to the result. The trick is to NOT use sorbate or anything else to inhibit the yeast, then to prime in the same way you’d do for a beer, and to also add some pre-dissolved lactose. I’d recommend making up a lactose simple syrup (lactose dissolved in heated water) and adding to taste, but if you want just a recommended recipe most people are satisfied with around 1 to 2 pounds of lactose per 5 gal as a backsweetener. Keep in mind that lactose intolerant people will have a hard time with your cider if you choose to go this way!

On Apr 9 2007, at 04:34 PM, hiddendragonet wrote:

FWIW, I use 2 pounds of lactose in my 5 gallons of cider. Lactose isn’t very sweet, and frankly I doubt you’d even really notice 1 pounds. Two pounds is perfect to give it just a wee hint of sweetness to take the bone-dry tart edge off, at least for my tastes. I like it because like Wayne said, I can sweeten a bit and still bottle carbonate.

On Mon Mar 26, 2007 2:49 pm, hiddendragonet wrote:

Yup, I’ve made 20 gallons of cider this way, with 2 lbs. lactose per 5 gallons. It’s become my standard. For those interested, 2 lbs. sounds like a lot but it really only sweetens it up a little bit because lactose isn’t very sweet. It’s the only way I could find to sweeten naturally while still carbonating in the bottle. Otherwise cider is bone dry.

On Tue Jan 03, 2006 3:00 pm, hiddendragonet wrote:

I saw how hard it would be to get 2 pounds of lactose to dissolve in my cider, so first I boiled a pint of water, added ¾ cups dextrose for priming, and boiled for 5 minutes. Then I added about a quart or more of cider to the pot, raised the heat, and added the lactose. I had it at high heat for 5-10 minutes, stirring constantly. It looked just like milk! As the cider approached the boiling point, the lactose finally dissolved quickly. A couple of stirs and it was finally clear.

In Nov, 2004, Paul Zocco wrote:

You are now at the stage of finalizing, modifying and bottling. If your cider lacks tartness/acidity, you can add malic acid — the acid found in apples — or an acid blend, as used by many winemakers and meadmakers. Try adding 0.5 ounces (14 g), then taste and add more if needed. Likewise, if it lacks sharpness, you can add tannins by adding grape tannins. Start with ½ tsp., then add more if taste dictates. If your original sweet cider was a bit low in sweetness or body, you may end up with an extremely dry and flavorless cider.

If you prefer a bubbly version, you would then add three quarters of a cup of corn sugar and a package of Champagne yeast to your 5-gallon (19 L) batch, and proceed to bottle. (If you’ve added sorbate solution to your mix, the carbonation will not work.)

Why do you add Champagne yeast?

On Mon Mar 26, 2007 11:39 am, hiddendragonet wrote:

I let my cider completely drop clear in secondary. This usually takes 2-3 months. Then I prime with ¾ cup dextrose and bottle. No extra yeast is added, and it carbs up every time no problem.

On Mon Jun 11, 2007 12:06 am, BrewBoyTrev wrote:

Generally, that would be true, but when I make my ciders, they typically spend about 2 months in primary, and then 2-4 months in secondary, and another 4-6 months in a third carboy at cool cellar temps. By the time I bottle, I am making the assumption that there is little viable yeast left in suspension. Even if I’m wrong, the $1.50 is a small price to pay to ensure that I have adequately carbonated ciders.

On Sun Mar 25, 2007 5:20 pm, Pseudolus wrote:

Bottling without additional yeast would probably work, but I’d add half a packet anyway just as cheap insurance.

On Sat Jun 09, 2007 11:57 pm, BrewBoyTrev wrote:

At bottling, I add whichever yeast I used to ferment it. I rehydrate it in a little boiled and cooled water, then I pour the yeast and thawed juices into the bottling bucket.

On Wed Aug 15, 2007 5:12 pm, BrewBoyTrev wrote:

I simply rehydrate a packet of yeast, pitch it into my bottling bucket with the priming sugar (sugar, honey or juice concentrate), and then VERY GENTLY stir it to mix it. It works every time.

<

p>From this, I made my Red Cap Cider.

Stone Age IPA

I based this recipe on the Stone IPA clone in the December, 2008 Issue of Brew Your Own Magazine. The differences are mostly from ingredient substitutions and process differences.

As Jamil and John do in Brewing Classic Styles, I formulated this recipe to produce five gallons (19 L) of beer for packaging. I assume a loss due to trub of a half-gallon in the fermenter and another half-gallon in the boil kettle. That will leave six gallons (22.7 L) at the end of the boil. I assume a boil-off rate of about one gallon per hour, which means I need 7.5 gallons (28.4 L) at the start of the boil for a 90-minute full-volume boil. I use bagged pellet hops for all hop additions.

Recipe: Stone Age IPA

Brewhouse Efficiency: 70%

Pre-Boil Volume: 7.5 gallons (28.4 L)

BG: 1.050 (12.39 °P)

OG: 1.063 (15.44 °P)

FG: 1.019 (4.83 °P)

ADF: 69%

IBU (Rager): 60

ABV: 5.9%

Color (Morey): 4.7 SRM (9.3 EBC) – Gold

Boil: 90 minutes

| Grains | Weight | Percent |

|---|---|---|

| Rahr 2-Row Malt (1.7 °L) | 12.75 lb. (5.78 kg) | 93.6 |

| Briess Caramel (10 °L) | 14 oz. (397 g) | 6.4 |

| Hops | IBU | |

| Perle 7.8% AA, 90 min. | 0.56 oz (16 g) | 17.4 |

| Magnum 14.4% AA, 90 min. | 0.42 oz (12 g) | 24.1 |

| Centennial 9.2% AA, 15 min. | 2.0 oz (57 g) | 18.9 |

| Centennial 9.2% AA, dry | 1.0 oz (28 g) | 0 |

| Chinook 11.4% AA, dry | 0.5 oz (14 g) | 0 |

| Yeast | ||

| Wyeast 1968 London ESB |

Step by Step

This is a single step infusion mash at 1.56 qt./lb. with a batch sparge. Mix the crushed grain with 5.3 gallons (20 L) of 160 °F (71 °C) water to stabilize at 152 °F (67 °C) for 60 minutes. Vorlauf and lauter to collect 3.75 gallons (14.2 L) of wort.

Sparge with 3.75 gallons (14.2 L) of 170 °F (77 °C) water to bring the collected volume to about 7.5 gallons (28.4 L). Boil for 90 minutes. While boiling, add the hops as per the hopping schedule. Cool the wort to 68 °F (20 °C). Transfer to a sanitized 6.5 gallon (24.6 L) glass carboy fermenter.

Pitch yeast and aerate the wort. Hold at 66 °F (19 °C) until fermentation is complete. Add dry hops. Let the beer condition for one week and then bottle. Carbonate to 2.0 volumes using 3.0 ounces (85 g) corn sugar. Bottle condition for two more weeks. Enjoy your Stone Age IPA.

(17) Sunday, April 11, 2010 Brew Day

It’s another great day to brew. Today (4/11) I’m doing the BYO Stone IPA clone.

9:38 Finished mash/lauter/sparge calculations.

9:42 Yeast smacked.

10:30 Brewery set up. Heating strike water. Weighing grains.

10:49 Grains crushed.

10:56 Filling MLT with 160 °F strike water.

10:59 Mashing at 152 °F.

Note: Beiss Caramel 10L is very hard (crunchy) with a grainy flavor and very slight sweetness. Rahr 2-row has a much earthier flavor and is not as hard.

11:36 There’s a mocking bird running through her repertoire in a nearby oak tree. Sunny skies with a temperature of 61 °F.

11:44 Heating sparge water.

12:00 Vorlauff.

12:05 First runnings 19 Brix/1.076 SG.

Note: First runnings are DELICIOUS! Very sweet. Nice light color. The yeasties should be very happy.

12:10 Adding sparge water

12:15 Vorlauff.

12:18 Sparging. Gravity of second runnings 9 Brix/1.035 SG.

Note: Second runnings not as sweet as first. Subtle earthy flavor.

12:22 Combined wort 12.4 Brix/1.049 SG (BG). Expected 1.050. Sight glass says about 7⅜ gallons, but the kettle is leaning back a bit because the ground under the camp stove is uneven so I’m going to call it 7½ gallons, which was the target.

Note: About the level of sweetness of hot cocao.

12:26 Heating to boil.

12:34 Dumped spent grain on compost pile.

12:54 Measured out boil hops.

Note: Drinking a Stone IPA while brewing a Stone IPA clone. How fitting. Thank you, Gretchen, for thinking of it and joining me.

1:02 Boiling. I can see the hot break this time. It does look like egg drop soup. I still have no idea why I could not see it last time. Adding bittering hops.

2:14 Placed chiller in kettle to sanitize.

2:19 Adding flavor/aroma hops and whirlfloc tablet.

2:28 Sanitize fermenter.

2:34 Flame out. Chilling.

2:56 Chilled to 68 °F. Removing chiller, whirlpooling, and cover.

3:06 15.2 Brix/1.060 SG (OG). Expected 1.063 (1.065).

3:12 Draining to fermenter.

3:38 Aerating.

3:41 Pitched. Fermenting at 66 °F.

4:25 Everything put away.

Update: It is Monday (4/12) and when I went to see how my beer was doing, I noticed the thermostat for the fermentation chamber heater was on. It was set for 66 °F, but it was reading 60°F, so I investigated further. Turns out I did remember to put the temperature probe into the thermowell in the carboy, but I forgot to wrap the fermwrap heater around it. It was desperately trying to heat the carboy, but it did not have much of a chance since it was a few feet away. Easy enough to fix, but my streak of messing something up every batch is still unbroken. They say that colder fermentation can be cleaner, so I do not think this will be a problem.

Update: It is the next Monday (4/19) and I just added the dry hops.

Update: It is the next Sunday (4/25) and I’m bottling. The gravity measures 7.6 Brix/1.011 FG. Expected 1.019. Wow. 80.9% ADF. 6.5% ABV. I have to assume that my mash lost temperature (or my thermometer reads high) and my wort was much more fermentable than I expected. The beer had been fermenting at 64 °F. I got 51½ bottles (618 oz or 4.8 gallons). I used 3 oz of corn sugar. I should end up with about 2.2 volumes of CO₂.

Commemoration Ale

I based this recipe on Mike “Tasty” McDole’s award-winning American IPA (a Sierra Nevada Celebration Ale clone).

As Jamil and John do in Brewing Classic Styles, I formulated this recipe to produce five gallons (19 L) of beer for packaging. I assume a loss due to trub of a half-gallon in the fermenter and another half-gallon in the boil kettle. That will leave six gallons (22.7 L) at the end of the boil. I assume a boil-off rate of about one gallon per hour, which means I need 7.5 gallons (28.4 L) at the start of the boil for a 90-minute full-volume boil. I use bagged pellet hops for all hop additions.

Recipe: Brush Valley Brewing Commemoration Ale

Brewhouse Efficiency: 70%

Pre-Boil Volume: 7.5 gallons (28.4 L)

BG: 1.054 (13.33 °P)

OG: 1.068 (16.59 °P)

FG: 1.016 (4.08 °P)

ADF: 75%

IBU (Rager): 84

ABV: 6.9%

Color (Morey): 13.7 SRM (35.2 EBC) – Light Copper

Boil: 90 minutes

| Grains | Weight | Percent |

|---|---|---|

| Rahr 2-Row Malt (1.7 °L) | 13.0 lb. (5.9 kg) | 81.3 |

| Briess Carapils (1.5 °L) | 1.0 lb. (0.45 kg) | 6.3 |

| Briess Caramel (60 °L) | 1.0 lb. (0.45 kg) | 6.3 |

| Briess Caramel (120 °L) | 0.5 lb. (0.227 g) | 3.1 |

| German Munich Malt (8.3 °L) | 0.5 lb. (0.227 g) | 3.1 |

| Hops | IBU | |

| Chinook 11.4% AA, 60 min. | 1.0 oz (28 g) | 42.9 |

| Centennial 9.9% AA, 15 min. | 2.0 oz (57 g) | 19.9 |

| Cascade 7.8% AA, 5 min. | 2.0 oz (57 g) | 10.9 |

| Cascade 7.8% AA, 1 min. | 2.0 oz (57 g) | 9.9 |

| Cascade 7.8% AA, dry | 1.0 oz (28 g) | 0 |

| Centennial 9.2% AA, dry | 1.0 oz (28 g) | 0 |

| Chinook 11.4% AA, dry | 1.0 oz (28 g) | 0 |

| Yeast | ||

| Wyeast 1056 American Ale |

Step by Step

This is a single step infusion mash at 1.375 qt./lb. with a batch sparge. Preheat the mash tun. Mix the crushed grain with 5.5 gallons (21 L) of 164 °F (73 °C) water to stabilize at 151 °F (66 °C) for 60 minutes. Vorlauf and lauter to collect 3.75 gallons (14.2 L) of wort.

Sparge with 3.75 gallons (14.2 L) of 170 °F (77 °C) water to bring the collected volume to approximately 7.5 gallons (28.4 L). Boil for 90 minutes. While boiling, add the hops as per the hopping schedule. Cool the wort to 68 °F (20 °C). Transfer to a sanitized 6.5 gallon (24.6 L) glass carboy fermenter.

Pitch yeast and aerate the wort. Hold at 68 °F (20 °C) until fermentation is complete. Add dry hops. Let the beer condition for one week and then bottle. Carbonate to 2.0 volumes using 3.0 ounces (85 g) corn sugar. Bottle condition for an two additional weeks. Enjoy your Commemoration Ale.

(16) Vernal Equinox 2010 Brew Day

Going to brew commemoration ale today (3/21)…

Ground the grains last night (3/20).

10:04 Strike water is hot. Started targeting 5½ gallons. Forgot to close valve on kettle. Guessed a quart lost. Added more. Ended up reading 6 gallons on sight glass.

10:08 Mashing. Mash temperature 158 °F. Added ½ g. 67 °F (tap) water. Settled at 152 °F. Mash volume just under 8 gallons.

10:48 Heating sparge water.

11:08 Vorlauf twice. ½-gallon Each. Temp 147 °F.

11:13 Lautering. Gravity of first runnings is 18.3 Brix. 1.073 SG.

11:18 First runnings collected. Sight glass says 4½ gallons.

11:24 Added sparge water. About 3¼ gallons.

11:34 Sparging. Starting with two ½-gallon vorlauf. Then collecting 3 gallons.

11:43 Sparge complete. Gravity of second runnings is 7.4 Brix. 1.029 SG. Total collected volume 7¼ gallons by sight glass. Boil gravity 13.7 Brix. 1.054 SG. Nailed it!!!

11:45 Heating to boil.

12:23 209 °F but rolling. I’m calling it a boil. Starting 90 min timer.

12:27 Boil over. Just barely. Don’t think it will effect anything.

12:36 Dumped spent grain on compost pile and rinsed MLT.

12:56 Bittering hops added.

1:41 Flavor hops added. Put immersion chiller in kettle to sanitize.

1:51 First aroma hop added.

1:55 Second aroma hop added.

1:56 Cooling.

2:20 Chilled. Original gravity 17 Brix. 1.068. Nailed it!!! Final volume 5⅓ gallons by sight glass. Draining to fermenter.

2:45 Aerating.

2:50 Pitching.

3:00 In fermentation chamber at 68 °F.

4:08 Everything cleaned and put away.

Next morning (3/22) I remembered to put sanitizer in the air lock. There is activity but it’s pretty weak.

So. Now that I have a chance to think I realize that I didn’t do some things. Nothing tragic, but if I’m taking notes i should have.

I tasted the grains as I was grinding them but I didn’t write my observations down. I remember the two-row was delicious and the dark kilned caramel was not but nothing in between and I have no record of my observations.

The other thing I didn’t do was taste the wort. Every time I took a gravity reading I should have tastes the wort. First and second runnings. Pre- and post boil. It might be interesting to taste the mash. It would also be good to taste the beer before carbonation.

Tuesday evening (3/23) I noticed that the beer temperature was 72 °F. The ambient temperature had warmed up during the day and wasn’t providing enough cooling capability. Fortunately the forecast for the evening was to be quite cold. I cracked a window and opened the panels on the fermentation box. After a few hours the temperature was down to 69 °F and was 66 °F by morning (that’s actually a bit low for what I had in mind).

There was also an issue with the Wyeast smack pack. It was partially inflated and I couldn’t get enough pressure on the nutrient pack to break it. When I pitched, a lot of the yeast appeared to be stuck in the package. I managed to break the nutrient pack once the smack pack was open, thinking that I could use it to rinse the yeast out of the outer pack with it. However, I managed to spray it all over the ceiling while breaking it open. So I think this batch is pretty severely underpitched. That and the temperature may result in a fairly strained yeast culture which may affect the beer flavor.

The following Saturday (3/27) I swirled the carboy and started raising the temperature targeting 70 °F for a diacetyl rest.

The following Monday (3/29) I added the dry hops. Gravity read 8.4 Brix (uncorrected) or 1.012 final gravity. Predicted final gravity was 1.016, so I’m guessing my wort was a little more fermentable than expected. That will give me an ABV of 7.5% when I expected 6.9%.

That coming Thursday (4/1) and Friday (4/2), the hops had begun to sink and settle to the bottom of the carboy. I swirled the beer in the carboy to re-suspend some of it and get as much out of them as I could.

Saturday (4/3) I bottled. I went with 2.2 volumes of CO₂. The beer finished fermenting at 70 °F. My calculations showed that I needed 0.84 ounces per gallon. I estimated that I had five gallons in the carboy, so that made 4.2 ounces total. I used 2 cups of water. I ended up with 12, 22-ounce bottles and 24, 12-ounce bottles (552 ounces, or 4.3125 gallons). That gave me 0.97 ounces per gallon, which should result in something under 2.7 volumes of CO₂, which is pretty high.

Here it is, the Tuesday after bottling (4/6). I had noticed the beer did not clear very well. I figured there was a lot of suspended yeast that would settle in bottle conditioning. I wondered if it was the amount of dry hops I had added leaving a haze of resins. Then today I was walking across campus while listening to a brewing podcast. They started talking about clarifiers. Then I remembered. I did not use one. I had not added it to my recipe and come brew day I forgot. I would normally use Irish moss or Whirlfloc. I do not know why I missed it this time. It will still be beer though.

It’s Wednesday (4/7). I found some leftover grains from the brew. I don’t have everything, but it’s worth tasting and recording what I do have.

The two-row is terrific. I would eat this as a snack or with breakfast. I had some trepidation when I first tasted my brewing grains. My wife rolls her own (our) oatmeal and every once in a while an oat sneaks through that still has the hull intact. Let me tell you, those things are inedible. GET THIS THING OUT OF MY MOUTH. NOW! For some reason, malted grains are not like that. I’ll gladly eat their husks. Anyway, I digress. The two-row is lightly flavorful. Unsurprisingly a bit like the insides of malted milk balls. The Munich malt has a very similar flavor, but ever-so-slightly sweeter. The Caramel 120L has a slightly burnt taste to it. Like the un-popped popcorn hulls in the bottom of the bowl that you eat anyway.

I mentioned that I hadn’t added any clarifier. The other thing I noticed, or rather that I had not noticed, that I had expected to notice was hot break and cold break. I have heard that one of the differences between extract and all grain is the presence of hot break and cold break. I have heard it described as being like egg drop soup. Well, I did not notice any of that. It seemed much like the extract brews I have made.